What is Whole Body Vibration (WBV) and what causes it?

The Control of Vibration at Work Regulations state we should be limiting the vibration levels employee’s are exposed to, including Whole Body Vibration (WBV). WBV is vibration that is transmitted into a person’s body through a seat or their feet.

Employees who drive/use machines where they are sat or possibly stood on the equipment, including forklift trucks, ride on mowers and quarrying or earth-moving machinery may be exposed to WBV which can cause an extensive range of potentially life changing health conditions.

Who is at risk of Whole Body Vibration exposure and what are the symptoms?

Exposure to whole body vibration typically accumulates over time, with its effects building up gradually. This vibration often originates from industrial vehicles, but any mobile machinery or work vehicle can be a potential risk, particularly when driven on uneven terrain or used for long durations. It is worth noting that the risks may be present when using stand on suspended conveyors, stand on mowers etc

Any worker regularly exposed to vibration through their feet or seat is at risk from being affected by WBV exposure. The most common industries where workers face the highest risks are construction, forestry, horticulture, agriculture and mining. Generally, workers with more frequent exposure to vibration sources face a higher risk of WBV than those with less regular contact with the severity of the effects widely based on factors like age, gender, operator skill, and the age and condition of the equipment used.

Employees exposed to whole-body vibration may experience various symptoms that can affect their well-being and performance. At lower intensities it’s common for people to experience discomfort, back ache, fatigue and impaired concentration.

Employees may also aggravate existing musculoskeletal conditions at lower levels of exposure. At higher intensities employees may suffer from back pain, joint problems, headaches and a loss of balance and in more extreme cases, employees are at risk of injuries to the joints, ligaments, nerves and intervertebral discs. If employees do suffer injuries or develop conditions due to their work, your business may be left open to large compensation claims, fine and legal fees.

If you’re not sure how your business would defend itself when facing litigation, find out what your business can do in our blog. Click here for more.

Employer Responsibilities when it comes it WBV

As stated by the HSE, employers must take action to prevent risk from exposure to vibration. They need to consider whether there are other ways or machines that would eliminate the exposure to the vibration, especially where large shocks and jolts are involved. If this isn’t possible, the exposure should be reduced to as low a level as is reasonably practicable.

This includes:

- Introducing control measures whenever your employees’ daily exposure to vibration is likely to exceed the exposure action value.

- Not expose your employees above the exposure limit value.

Find out how to monitor the levels of exposure your employees are facing in our recent blog on our advanced WBV and HAV calculator alternatives.

How HAVSPRO can help you limit employees’ daily exposure to Whole Body Vibration (WBV)

While the conventional methods of monitoring levels of vibration recognise there may be a potential risk to the operator, they don’t take advantage of modern technology. Without clearly identifying exactly what the risks are, when and why they arise, it becomes very challenging to take appropriate action, produce accurate and meaningful Risk Assessments that give you the guidance to reduce the risks to ALARP.

At HAVSPRO, we take health and safety seriously, and believe that without this precise identification, adequate risk mitigation is far more challenging than it needs to be, possibly even impossible to accurately identify the actual risk.

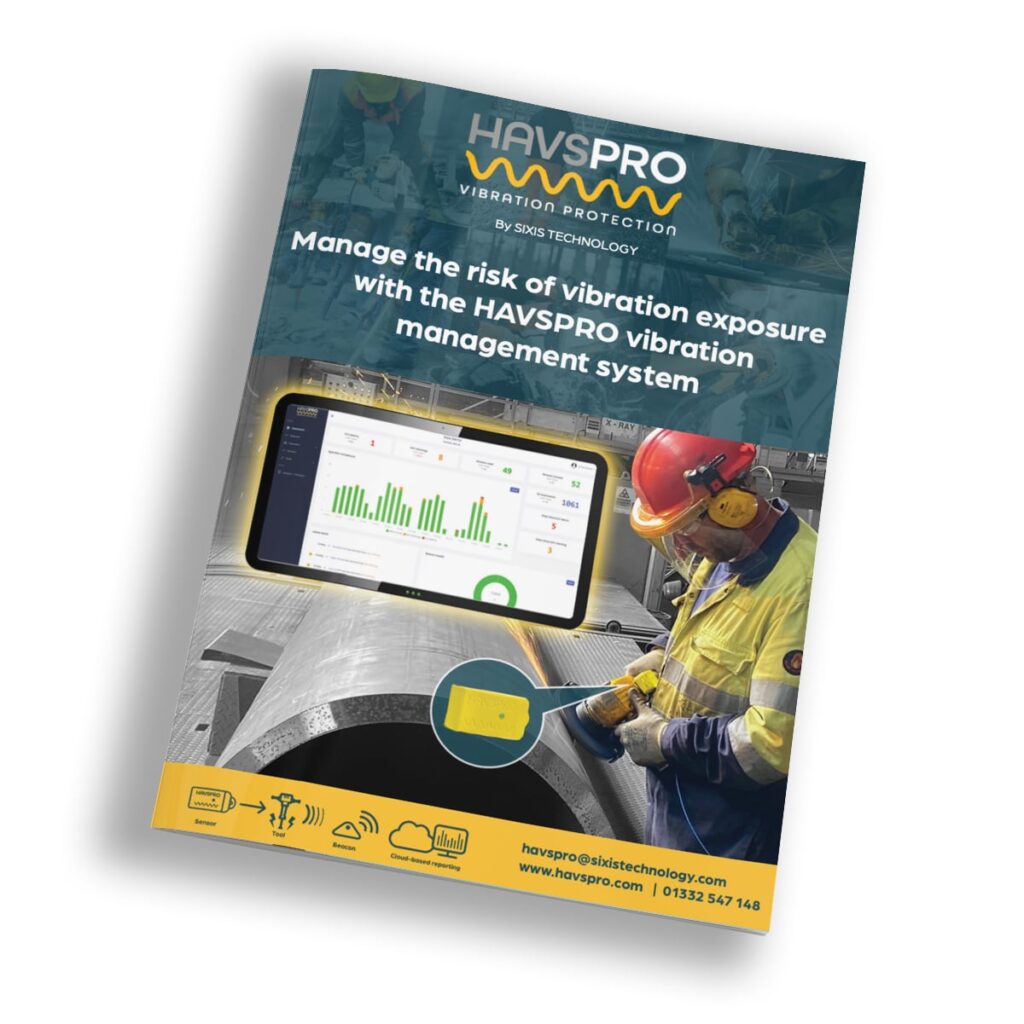

We have developed a simple to use tool-mounted system that eliminates the need for manual HAV and WBV Calculators, ensuring accurate data recording and allowing accurate data guided interpretation without any room for error. By utilising this methodology you can effect change in the correct area, record the actions and prove that the efforts being applied will unequivocally protect your business and your employees

Our tool-mounted sensors, personalised to each operator, attach to dedicated holsters fitted to individual tools and machines, programmed with specific tool/machine details, we don’t use assumed data, we measure as the operator experiences regardless of any influencing factors such as terrain, tyre pressures, machine condition, weather conditions or conveyor supports used. You can even identify operator training needs or maintenance issues.

Complete the form below to download our brochure and find out more about how your business can get a grip on WBV & HAV control.