The vibration Regulations require employers to:

To protect employees, and to comply with the Control of Vibration at Work Regulations 2005

- Employers need to assess the risks from vibration and implement measures to control them.

- Regulation 3(4) applies to all the employers involved and each will have a responsibility: (a) to their own employees; (b) so far as is reasonably practicable, to anyone else who is exposed to vibration in work activities under their control

- Provide information, instruction and training to employees on the risk and the actions being taken to control risk and provide suitable health surveillance.

- Reduce the risk to As Low As Reasonably Practicable.

The Vibration Regulations include an exposure action value (EAV) and an exposure limit value (ELV) based on a combination of the vibration at the grip point(s) on the equipment or work-piece and the time spent gripping it.

How can HAVS and the risks associated with it be controlled?

The Control of Vibration at Work Regulations 2005 aims to ensure that individuals do not experience harm to their health due to hand-arm vibration. As an employer, you should be focused on managing and mitigating the risks associated with exposure to vibration.

But how do you effectively measure and monitor the exposure levels?

You can use manufacturers data and then add the K factor, use assumed data which is accurate only at the time it was measured, use tool timers based upon the values above or ask the users to tell you how long they’ve used the tools for and then use the HSE ready reckoner…..then, apply the measures and actions necessary to reduce or eliminate the risk it isn’t easy is it!

Is “guesstimated” data enough when it comes to preventing potentially life changing disabilities? We think not which is why we have invested in the technology to allow you to understand where the actual risk is!

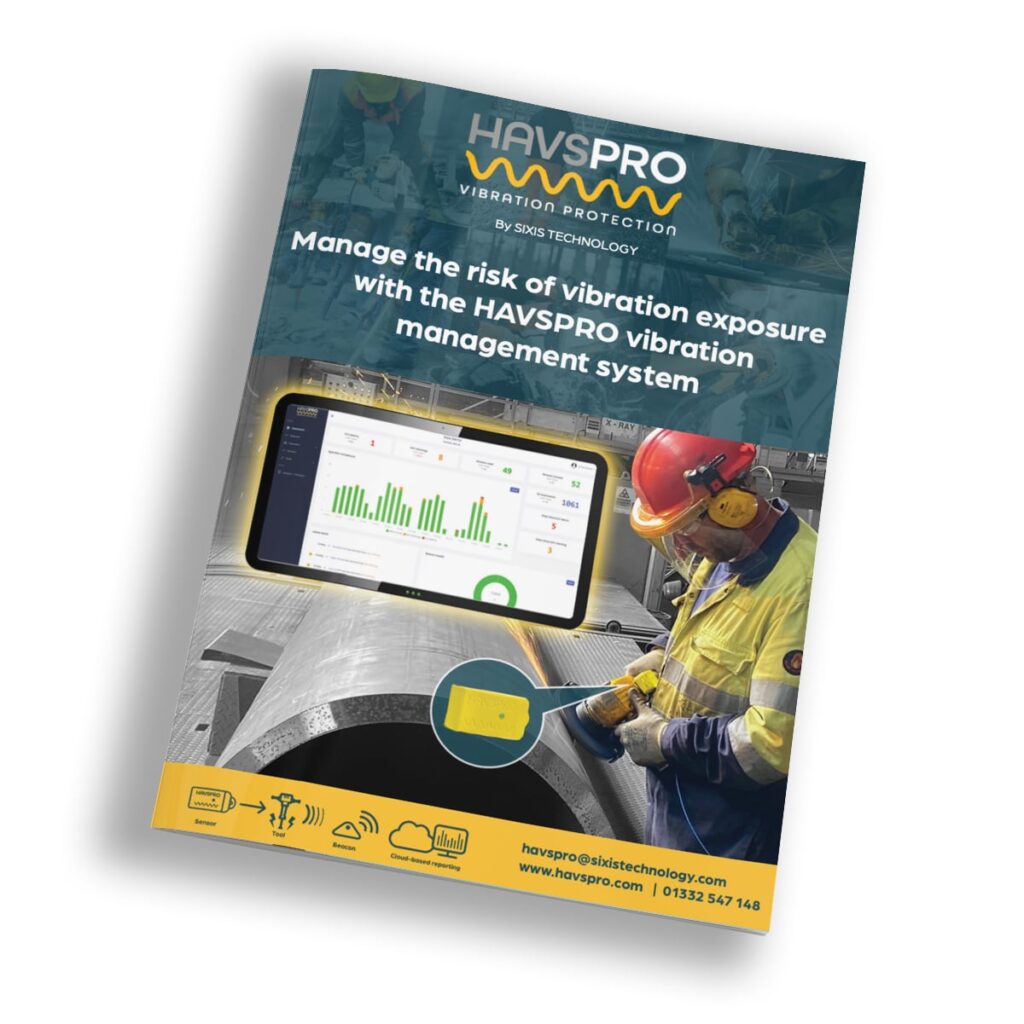

The HAVSPRO Technology

With HAVSPRO, you have the power to continuously and accurately measure and monitor the exposure levels each operator is exposed to on each task via a personalised sensor programmed to the user with their specific HSE point values. The operator simply clicks the sensor onto a holster which is mounted on the tools, does the job and removes, then onto the next tools etc.

Each task is recorded and reported, allowing you to analyse and understand the activity within each step and to understand where the real risks actually are, based upon facts not guesstimates. The ability to identify spikes in magnitude guides you to the actual cause of the problem within that specific task which in turn gives you clarity of your Risk Assessments, clear understanding of tools/consumables suitability and guides you to reducing or eliminating the risk.

Accurate data enables data driven decisions around effective risk assessments and reassuringly gives valuable guidance in achieving ALARP, and your actions can all be recorded on the cloud based reporting platform.

Complete the form below to download our brochure and find out more about how your business can get a grip on HAV control.